Driltech Case Study

Driltech is a leading manufacturer of quality rotary

blast hole drilling machines.

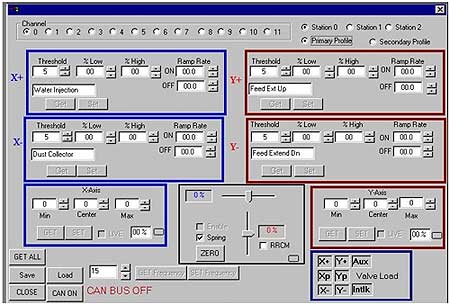

The Driltech multiplex system differs from that of typical

Class 1 customers because of the extensive electro hydraulic

control requirements. Driltech required proportional

control of over 30 separate functions. To accomplish

the electro hydraulic proportional control Class 1 employed

their Ramp Rate Control Module (RRCM) also known as

the Joystick Controller. The RRCM coupled with the Proportional

Valve Driver Module (PVDM) is responsible for all electro

hydraulic control on the drill, including the propel

or tram circuit, the rotation circuit, the feed or pull

down circuit and all pipe handling and auxiliary circuits.

The RRCM PVDM combination allows Driltech unequalled

programmability of their proportional valves. Each valve

can be programmed to operate in two profiles. Within

each profile the ramp on/off time, threshold (dead band),

the low and high PWM can be set. Each PVDM represents

a channel and the PWM frequency can be set from channel

to channel.

Driltech chose the Class 1 ES-Key System because it

utilizes a Control Area Network (CAN). The Es-Key system

allows their entire electrical system, including their

electro hydraulic control to reside on the same network.

Driltech really wanted to capitalize the benefits of

the ES-Key System by locating all of the operator controls

in the seat. This would have been impossible with a

conventional system due to the number of wires necessary

to control such a complex piece of machinery. Even with

the AM/FM CD player installed in the seat there were

less than 10 wires that had to be routed through the

seat swivel.

After the inputs and outputs were defined, the machine

was set up in zones that strategically located the ES-Key

nodes close to their operating points. Nodes were placed

near the engine, in the seat, at the base of the mast

near the hydraulic pumps and on the mast itself. Every

possible function was multiplexed, from the automatic

ether injection system for cold starting to the pipe

handling and drill system functions on the mast.

The Driltech drill has been an excellent proving ground

for the ES-Key system. The rugged environmental conditions

of the mining industry showcase the reliability of the

ES-Key system. Not only are there the typical moisture

and extreme temperature concerns, but also the vibration

levels reach extraordinary benchmarks. Quality and reliability

make Class1 and Driltech a formidable team.

|