| Case Study

Daimler Chrysler Commercial Bus

The challenge: Take a conventionally wired bus and convert

it into a fully multiplexed bus.

In today’s competitive market place

engineers are seldom afforded the luxury of being able

to completely redesign a product. More often than not

all engineering time is spent in support of existing

product, designing customer specified options and putting

out the day-to-day fires. At Class 1 we realized that

this was just the case at Daimler Chrysler Commercial

Busses (DCCB). So we offered the unprecedented service

of taking one of their conventionally wired SLF 235

Super Low Floor Busses and multiplexing it. Since their

engineering time was at a premium and Class 1 wanted

to tap into new industries, the joint project was a

perfect match.

After receiving the SLF 235 at our facility

we went right to work. We identified the inputs and

outputs on the bus and insured that we understood the

functionality. Once the input output list was established,

we divided the vehicle into zones; the front power panel,

the dash, the drivers’ side panel, the left front

overhead, the right front overhead, the rear door area

and the rear overhead. At the request of DCCB engineering

we located all ES-Key nodes in the interior of the bus.

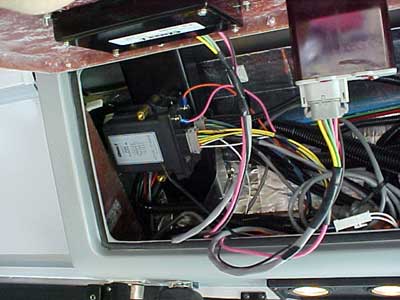

The front power panel zone is located

just inside the entry door. It is provided to DCCB as

a completed sub-assembly that allows them to simply

install and plug it in. In addition to handling both

12 and 24-volt power distribution for the front half

of the vehicle, it is also responsible for headlamp

control (with DRL), ramp and kneeling functions.

The dash area contains the USM and several

input and output nodes. The kneel and ramp controls

and all lighting switches are in the dash as well as

important operator indicators such as “check engine”

and “door open”.

The drivers’ side panel zone contains

the transmission ECU the ABS computer and three ES-key

nodes. The ES-Key nodes receive inputs from and give

outputs to the transmission ECU and the ABS computer

as well as receive inputs from the door control switch.

This is also an intricate sub-assembly provided by class

1.

The left front overhead zone houses two

power distribution modules (PDM), the Es-Key information

center and the data logger. The PDM’s control

such functions as the left side interior lights the

stop request sign and the left side marker lights.

The right front overhead zone has two

more ES-Key PDM’s. They control right side interior

and exterior lighting as well as the front entry door.

The ES-Key system provides complete entry door control

eliminating the necessity to purchase a separate controller.

The rear door area zone has only one ES-Key

PDM dedicated to rear door control and lighting. The

rear door control is complete with sensitive edge operation

that will automatically open the rear door if an obstruction

is sensed during closure. The door remains open until

the operator intervenes by cycling the door control

switch.

The rear overhead zone has several ES-Key

nodes and the rear bus 12/24-volt power distribution.

This is also provided to DCCB as a drop in sub-assembly.

The rear overhead zone is where the ES-Key system interfaces

with the engine and where all of the rear exterior lighting

is controlled. The engine interface even includes a

starter lockout feature that will not allow the engine

to be started unless all safety interlocks are met.

The end results were fantastic! We were

able to successfully multiplex the SLF 235, saving the

customer valuable engineering time and money. Besides

the obvious benefits of multiplexing, such as onboard

diagnostics, fewer light duty mechanical parts, and

many less electrical connections, DCCB realized a weight

reduction of over 150 pounds. That’s enough weight

to add another passenger.

At the time of this writing we are approaching

200 “fielded units” with outstanding customer

satisfaction. Class1 would like to thank the people

at Daimler Chrysler Commercial Busses for the opportunity

to work with them. Their co-operation and commitment

to quality have proven them to be a force in the transit

bus industry.

|